Customized Fan Solutions For Food Processing Plants

2025-07-08

In food processing plants, maintaining proper ventilation and air quality is crucial for both product safety and operational efficiency. The environment in such facilities requires reliable airflow management to control temperature, humidity, and airborne contaminants. Customized fan solutions play a vital role in meeting these unique demands, and understanding the right types of fans to use is essential. Among the key components often integrated into these systems are the performance blower, roof ventilator for home, and industrial centrifugal fan—each serving specific purposes tailored to food processing needs.

Food processing plants vary widely in their size, layout, and processing methods, which means that a one-size-fits-all approach to ventilation is preciously effective. Customized fans can be designed to address the particular airflow challenges in different zones of the plant, from raw material storage to cooking, cooling, and packaging areas. A performance blower is frequently selected for its ability to generate steady, powerful airflow in tightly controlled spaces. These blowers provide precise air movement that can help regulate humidity and temperature, critical factors in preventing spoilage and maintaining hygiene standards.

In addition to indoor airflow management, exhaust and ventilation systems need to be efficient and well-integrated into the building structure. This is where a roof ventilator for a home can be adapted for industrial use. Though originally designed for residential ventilation, this type of ventilator can be customized to fit the larger scale and higher performance requirements of a food processing facility. Its primary function is to exhaust hot, stale air and draw in fresh air, reducing internal heat buildup and improving air circulation. Using roof ventilators strategically can help maintain a safe and comfortable working environment, which ultimately supports production consistency.

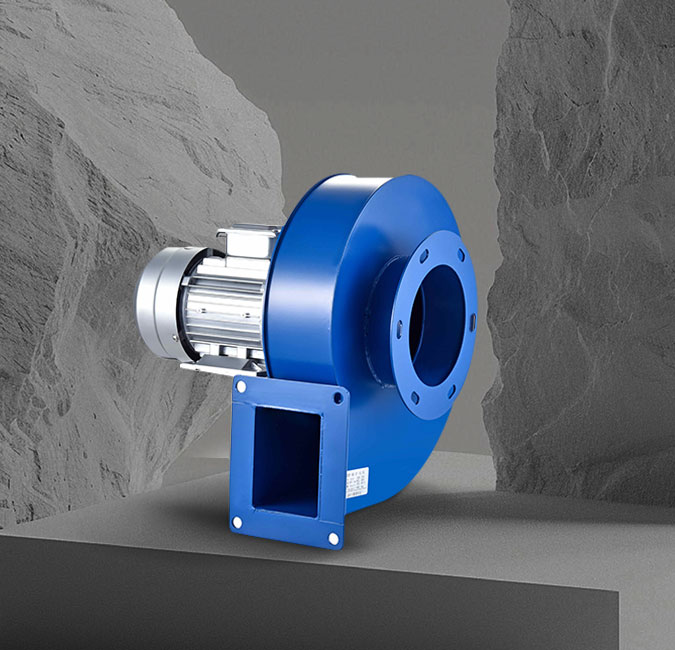

The industrial centrifugal fan is another critical piece of the ventilation puzzle in food processing plants. Known for its capability to handle high static pressures, this type of fan is often used where air needs to be moved through ductwork, filtration systems, or scrubbers. Its robust design allows it to sustain continuous operation under demanding conditions, which is typical in food processing environments. An industrial centrifugal fan can also be customized in terms of materials and coatings to resist corrosion or contamination, which is important for compliance with food safety regulations.

One of the benefits of opting for customized fan solutions is the ability to integrate multiple types of fans, such as performance blowers, roof ventilators for home, and industrial centrifugal fans, into a comprehensive system that addresses the full spectrum of ventilation needs. For example, a food processing plant might use performance blowers in critical areas where airflow precision is required, while installing roof ventilators for homes on the building exterior to facilitate natural ventilation. Simultaneously, industrial centrifugal fans could be employed within the duct systems to maintain consistent pressure and move air efficiently throughout the facility.

Beyond airflow and temperature control, customized fans also help in maintaining air cleanliness. Food processing plants often face the challenge of airborne particles, dust, or odors, all of which must be managed to comply with health standards. A well-designed system using industrial centrifugal fans can support filtration units that remove contaminants before air is recirculated or exhausted. Similarly, performance blowers can assist in creating positive or negative pressure zones to control the spread of dust or microbes.

Choosing the right fan for each application within a food processing plant requires careful assessment of the plant's operational conditions. Factors such as air volume, static pressure, noise levels, and space constraints all influence fan selection. Customized solutions can be developed after thorough site analysis and consultation, ensuring that each performance blower, roof ventilator for home, and industrial centrifugal fan fits the exact requirements of the facility.

Installation and maintenance considerations also come into play with customized fan systems. For example, a performance blower may be designed for easy access to facilitate routine cleaning and servicing, which is vital in food processing environments to avoid contamination. Similarly, roof ventilators for home use adapted for industrial use must be constructed to withstand weather conditions while remaining energy efficient. Industrial centrifugal fans, often running continuously, require durable materials and designs that simplify maintenance schedules.

Overall, customized fan solutions provide food processing plants with a flexible and efficient approach to ventilation and air management. By integrating specialized equipment such as performance blowers, roof ventilators for homes, and industrial centrifugal fans, these facilities can maintain the environmental controls necessary for food safety and operational success. The ability to tailor fan systems to the specific needs of a plant means better control over airflow, improved worker comfort, and adherence to regulatory standards.

In conclusion, the ventilation demands of food processing plants call for thoughtful design and precise equipment choices. Customized fans not only enhance airflow and temperature control but also contribute to cleaner air and safer working conditions. Whether it’s a performance blower ensuring steady airflow in critical zones, a roof ventilator for home adapted to improve building ventilation, or an industrial centrifugal fan managing air movement through complex duct systems, each element plays an integral role in creating an effective ventilation strategy tailored to food processing environments.

English

English русский

русский عربى

عربى