Proper Lubrication For Industrial Fan Motors

2025-07-08

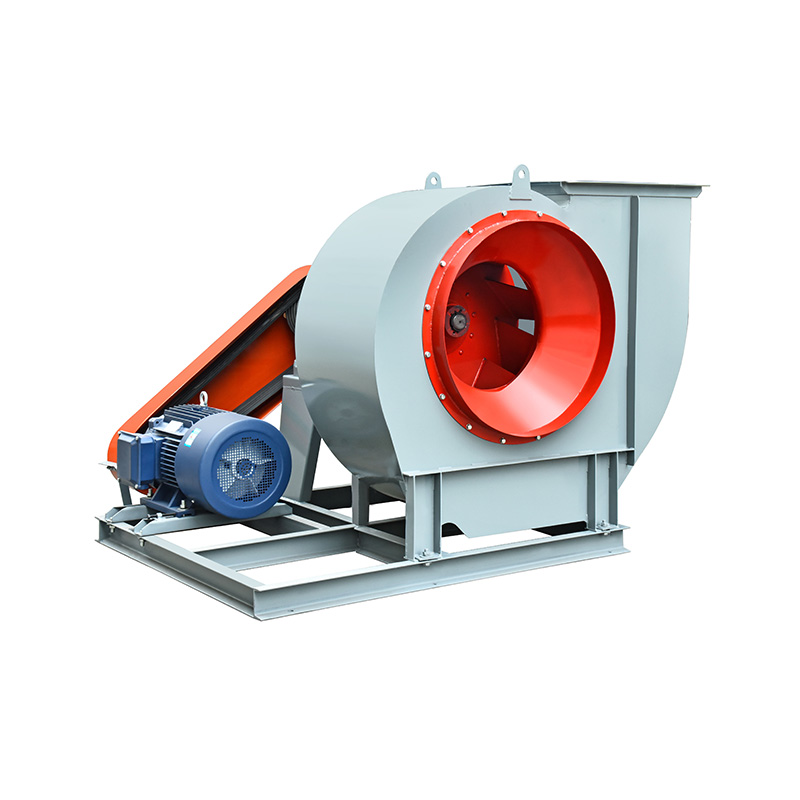

Proper lubrication is a critical factor in maintaining the efficiency and longevity of industrial fan motors. Whether you're working with a blower for motor applications, a high powered industrial fan, or a variable speed centrifugal fan, understanding lubrication practices helps ensure smooth operation and less downtime.

Industrial fans are essential components in many manufacturing, processing, and ventilation systems. A blower for motor units, for example, relies heavily on the motor’s ability to function without interruption. When lubrication is neglected or improperly applied, it can lead to premature bearing failure, overheating, and costly repairs. This applies equally to high-powered industrial fans, which often operate continuously under demanding conditions, as well as variable speed centrifugal fans that require precise motor control for good airflow.

One of the key aspects of proper lubrication is selecting the right lubricant for the motor’s bearings. Bearings are usually the more vulnerable parts in fan motors since they endure constant friction and load. Using a high-quality lubricant that meets the specifications for the particular blower for the motor model is essential. Some industrial fan motors require grease lubrication, while others might need oil. The choice depends on factors such as motor speed, temperature, and load. For example, a high powered industrial fan running at high speeds might need a lubricant that can withstand elevated temperatures and resist breakdown over time.

Regular maintenance schedules should include checking and replenishing lubrication. With variable speed centrifugal fans, lubrication intervals can vary because the motor does not run at a constant speed, which affects friction and heat generation differently compared to fixed-speed motors. Monitoring the motor’s operating conditions, such as temperature and vibration, can help determine the appropriate lubrication frequency. Ignoring these factors could lead to increased wear on the blower for motor components and, eventually, motor failure.

Another important consideration is the lubrication method. For many high powered industrial fans, automatic lubrication systems are available and highly recommended. These systems deliver precise amounts of lubricant at regular intervals, reducing the risk of over- or under-lubrication. In contrast, some variable speed centrifugal fans installed in less accessible locations might require manual lubrication, which emphasizes the importance of following strict maintenance protocols to avoid neglect.

Proper lubrication also involves using the right tools and techniques during application. Over-lubricating a blower for a motor can cause excess grease to escape from the bearing seals, attracting dust and contaminants that accelerate wear. On the other hand, insufficient lubrication leaves the bearings dry and prone to damage. Training maintenance personnel to apply the correct amount and type of lubricant ensures the longevity of the motor and the industrial fan as a whole.

Furthermore, it is important to consider the environment in which the industrial fan operates. For high powered industrial fans in dusty or humid conditions, lubricants with added protection against corrosion and contamination are advisable. Variable speed centrifugal fans used in cleanrooms or controlled environments may require food-grade or synthetic lubricants to meet health and safety regulations.

To summarize, proper lubrication is an indispensable part of maintaining industrial fan motors, whether it is a blower for motor setup, a high powered industrial fan, or a variable speed centrifugal fan. Attention to the type of lubricant, application method, maintenance intervals, and operating environment all contribute to improved motor reliability and performance.

Taking these steps helps reduce unplanned downtime and extends the service life of critical ventilation equipment. Properly lubricated motors operate more quietly and efficiently, which can also lead to energy savings over time. With consistent attention to lubrication practices, industrial fans will continue to meet performance expectations in various applications.

In conclusion, the role of lubrication cannot be overstated in industrial fan motor maintenance. A blower for motor, a high powered industrial fan, or a variable speed centrifugal fan all benefit from careful and regular lubrication to maintain smooth operation and reduce wear. Maintenance teams should prioritize lubrication schedules and adhere to recommended guidelines to keep fans running efficiently and reliably.

English

English русский

русский عربى

عربى