What Fire Safety Regulations Mean For Fan Design

2025-07-08

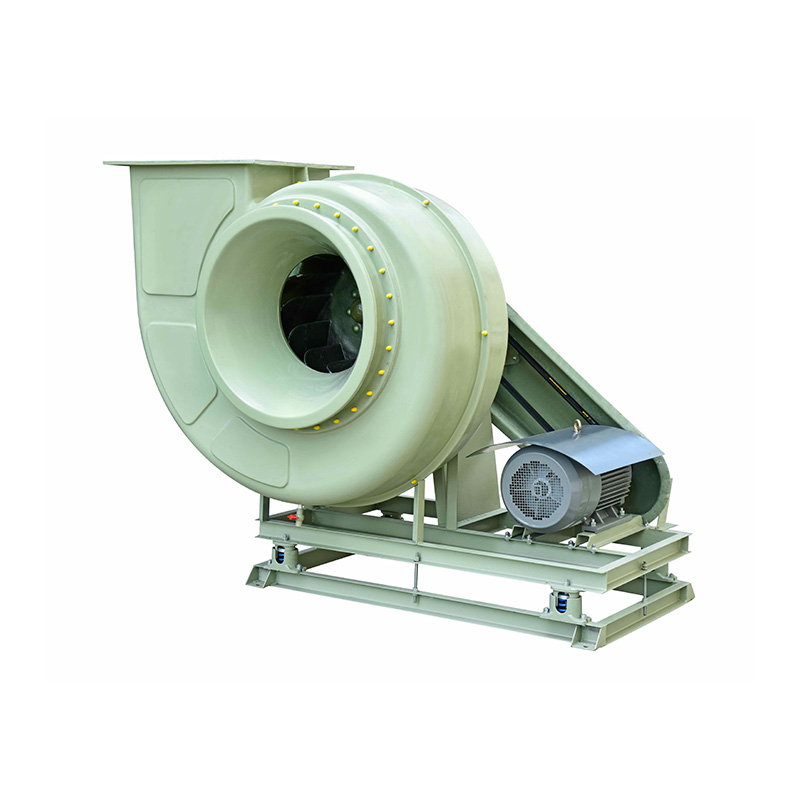

In the design and manufacturing of ventilation systems, fire safety regulations play a critical role in shaping product specifications and operational standards. This is particularly true for equipment such as the roof ventilation exhaust fan, ventilator industrial axial units, and axial fan ventilation systems, which are often installed in environments where fire safety is paramount. Understanding how these regulations influence fan design helps manufacturers deliver reliable and compliant products while meeting the specific demands of various industries.

Fire safety regulations are established to lessen the risk of fire hazards and to ensure the safety of occupants and property. These rules often include requirements regarding materials, fire resistance, smoke control, and electrical safety. When it comes to fans, especially roof ventilation exhaust fans, compliance means considering these factors at every stage of design.

One key aspect of fire safety regulations is the ability of a fan to withstand high temperatures and maintain operation during a fire emergency. Roof ventilation exhaust fans, for example, are commonly installed on building rooftops to remove heat, smoke, and toxic gases in case of fire. Their design must ensure that critical components such as the motor and impeller remain functional under elevated temperatures for a specified duration. This is essential for creating effective smoke evacuation pathways and reducing the spread of fire indoors.

Similarly, ventilator industrial axial fans are frequently used in industrial facilities where the risk of fire can be elevated due to the presence of flammable materials or processes. These fans must be engineered with fire-resistant materials or coatings and sometimes equipped with fireproof motors or heat-resistant wiring. The axial fan ventilation systems also need to be designed to avoid creating sparks or ignition sources. This includes selecting components that less friction and heat generation and ensuring that any electrical parts meet stringent fire safety standards.

In addition to material considerations, fire safety regulations often demand that fans provide reliable performance in smoke control. For roof ventilation exhaust fans, this means they should have sufficient airflow capacity and pressure to effectively clear smoke from escape routes and other critical areas. Proper fan selection and design directly impact the safety and evacuation efficiency during fire events. Engineers take this into account by carefully calculating airflow rates and selecting appropriate fan sizes to match the building’s ventilation needs.

The control and integration of axial fan ventilation units also tie into fire safety compliance. Many fire codes require that these fans be connected to fire alarm or suppression systems so that they activate automatically when smoke or heat is detected. This interlocking ensures timely ventilation and prevents manual errors during emergencies. Designers often include features such as variable speed drives and backup power sources to maintain operation even if the main power supply fails.

Maintenance and testing protocols are another element influenced by fire safety regulations. Roof ventilation, exhaust fans, and industrial axial ventilator fans must be regularly inspected to confirm they can perform their fire safety functions when needed. This includes checking for wear in fan blades, verifying motor integrity, and testing control system responsiveness. Proper maintenance guarantees that the fans will work efficiently and safely during fire emergencies, preventing potential system failures that could endanger lives.

Environmental considerations also impact fan design within the framework of fire safety. Roof ventilation exhaust fans are often exposed to outdoor conditions, requiring corrosion-resistant materials that do not degrade and compromise fire safety features over time. Similarly, ventilator industrial axial fans used in harsh industrial environments need robust construction to maintain their fire safety ratings despite exposure to chemicals, dust, or moisture.

In recent years, fire safety regulations have evolved to address emerging building designs and technologies. For example, the increased use of sustainable materials and energy-efficient buildings demands innovative approaches to axial fan ventilation design. Designers must balance energy conservation with fire safety by integrating smart controls that optimize ventilation without compromising emergency response capabilities.

In conclusion, fire safety regulations have a profound impact on how roof ventilation exhaust fans, ventilator industrial axial units, and axial fan ventilation systems are designed and manufactured. These rules ensure that fans not only meet airflow and ventilation requirements but also contribute to overall building safety during fire incidents. Compliance involves selecting appropriate materials, engineering for heat resistance, integrating control systems, and maintaining reliable operation under emergency conditions.

Understanding and applying these fire safety standards is essential for manufacturers and engineers aiming to provide ventilation solutions that protect lives and property. As building codes continue to evolve, staying informed about regulatory changes and technological advancements will remain a critical part of designing effective and safe ventilation fans.

English

English русский

русский عربى

عربى