Product

External Rotor Motor Fan Manufacturer

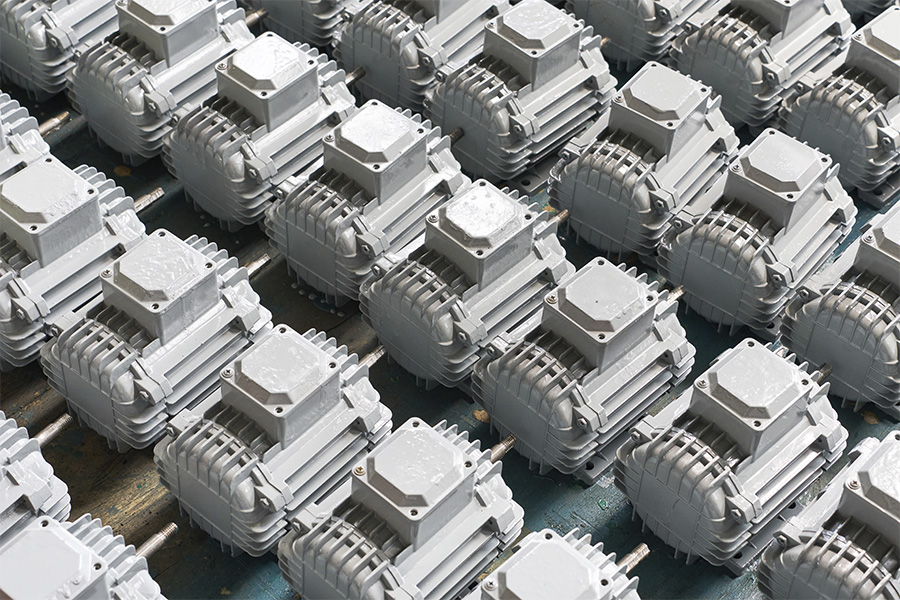

As a professional fan manufacturer and supplier, HAOBA has rich design and production experience in the field of external rotor fans. Our external rotor fans adopt a unique motor structure design, which directly installs the rotor on the fan housing, greatly reducing the overall volume and achieving a compact and lightweight product form. This design not only improves the heat dissipation performance of the fan, but also effectively reduces noise and vibration, ensuring the smooth and quiet operation of the fan.

The core advantage of HAOBA external rotor fans is also reflected in high efficiency and energy saving. By optimizing the matching of impellers and motors, our fans can output larger air volume and air pressure at lower power, meeting the diverse needs of ventilation in different industrial and commercial environments. At the same time, the external rotor fan has a simple structure and is easy to maintain, which greatly reduces the cost of use and maintenance.

Our products are widely used in air conditioning systems, air purification equipment, electronic cooling, medical equipment and other occasions that require high-performance fans. With exquisite manufacturing technology and strict quality control, HAOBA external rotor fans have established a good reputation in the industry and become a high-quality choice trusted by customers. We are committed to continuous innovation to provide customers with efficient and reliable fan solutions.

-

Feb 20, 2026_HaoBaEvery roof mounted ventilator — especially units equipped with Centrifugal Roof Ventilators — requires regular maintenan...Read More

-

Feb 13, 2026_HaoBaWater leakage through roof ventilation is a concern for many building owners, especially those using a roof mounted vent...Read More

-

Feb 06, 2026_HaoBaA roof mounted ventilator — especially when equipped with Centrifugal Roof Ventilators — is a critical component in indu...Read More

-

Jan 29, 2026_HaoBaIn applications from industrial ventilation to equipment cooling, many users consider an External Rotor Axial Fan when d...Read More

External Rotor Fan Industry Knowledge Extension

Understanding the External Rotor Fan in Industrial Ventilation

The external rotor fan is a widely used component in modern ventilation systems, especially in commercial and industrial settings where space and performance need to be carefully balanced. Unlike traditional motor setups where the rotor is housed inside the stator, an external rotor configuration reverses this arrangement. In this setup, the rotor encases the stator and often functions as the fan hub itself. This compact design allows for direct drive operation without needing a shaft or coupling, which not only reduces mechanical complexity but also contributes to a more streamlined air movement system. These fans are often used in air conditioning units, refrigeration systems, and ventilation ducts due to their space-saving design and relatively low noise levels.

External Rotor Axial Fan: Focused Airflow in a Compact Format

The external rotor axial fan is a specialized type of fan designed to move air along the axis of the impeller. Its configuration combines the advantages of axial airflow with the efficient motor design of an external rotor system. This combination makes it suitable for applications where space constraints require a flatter profile, such as in condenser units or ducted ventilation systems. The fan blades are directly attached to the rotor, and the motor is integrated into the impeller assembly. This design minimizes vibration and improves cooling of the motor due to constant airflow over the rotor surface. The external rotor axial fan is often selected for systems that need to maintain a consistent airflow across coils, heat exchangers, or electronic enclosures, offering a stable performance across a range of pressures.

External Rotor Motor Fan: A Compact and Efficient Air Movement Solution

The external rotor motor fan refers to a fan system that is built around an external rotor motor, a design where the motor’s moving part is placed on the outside and rotates around a fixed core. This type of fan is valued for its ability to integrate the motor and impeller into a single, compact unit. As the rotor directly drives the fan blades, the need for external transmission elements is eliminated. The compact nature of the external rotor motor fan makes it a common choice in applications such as evaporators, cooling units, and even HVAC systems in vehicles or small enclosures. Because of the direct-drive setup, these fans often operate quietly and steadily, which is particularly useful in installations where background noise must be minimized. Maintenance is also simplified, as there are fewer moving parts that require service over time.

Outer Rotor Fan: An Alternative Name, Same Reliable Functionality

The term outer rotor fan is often used interchangeably with external rotor fan, especially in various regional markets or product descriptions. It refers to the same basic motor concept: the rotor is positioned outside the stator and rotates the impeller directly. This configuration creates a low-profile and efficient structure, making the outer rotor fan suitable for use in applications where depth or available space is limited. These fans are frequently seen in ventilation grilles, extraction units, and compact air handling devices. The outer rotor design improves motor cooling since the rotating shell is in constant contact with moving air, reducing heat buildup. This feature contributes to longer motor life and consistent performance under continuous operation. The use of outer rotor fans is particularly notable in air curtain systems and wall-mounted ventilation where aesthetics, quiet operation, and compact dimensions are all desirable.

Summary and Common Benefits Across Designs

Across these fan types—whether referred to as external rotor fan, external rotor axial fan, external rotor motor fan, or outer rotor fan—the shared traits include a compact design, integrated motor-impeller structure, and suitability for confined spaces. While they serve slightly different roles depending on airflow direction or mounting needs, their structural efficiency and straightforward installation make them reliable choices in a variety of settings. Additionally, the direct-drive mechanism common to all these designs reduces the risk of mechanical failure due to belt or coupling issues. These fans are not only efficient in performance but also designed for practical use in environments ranging from data centers and retail ventilation systems to industrial cooling applications.

The flexibility in naming—whether you encounter "outer rotor" or "external rotor"—reflects regional or industry preferences, but the engineering principles remain the same. These fans continue to provide dependable performance where airflow, quiet operation, and compact form are necessary.

English

English русский

русский عربى

عربى