Product

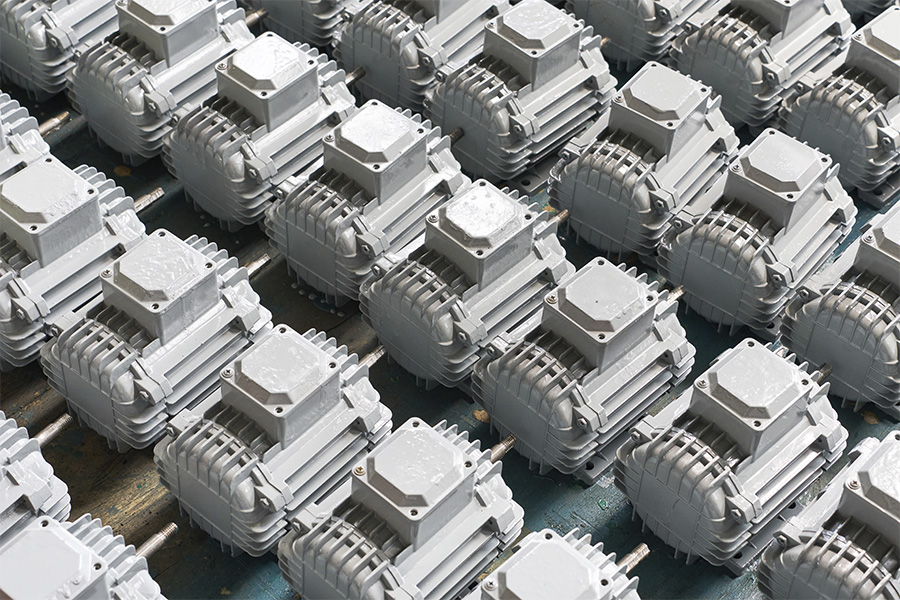

Wholesale Industrial Roof Ventilation Fan

Roof ventilators are ventilation equipment installed on the roof of a building, which can effectively exhaust indoor heat, moisture and harmful gases, improve air circulation and indoor environmental quality. It promotes air exchange through natural wind or mechanical drive, helps reduce indoor temperature, prevents the generation of moisture and mold, and protects the building structure and internal equipment from damage. Roof ventilators have a compact structure design and are usually made of weather-resistant materials. They have rain and dustproof functions to ensure long-term stable operation.

As an important part of the ventilation system, roof ventilators are widely used in industrial plants, warehouses, workshops, commercial buildings and large public facilities to effectively improve indoor air quality and protect personnel health and equipment safety.

HAOBA roof ventilators focus on efficient exhaust and energy saving in design, combined with low noise and durable performance to meet the needs of various complex environments. With high-quality manufacturing technology and strict quality management, HAOBA roof ventilators not only improve ventilation efficiency, but also provide customers with reliable solutions. They are an ideal choice in modern building ventilation systems.

-

Feb 20, 2026_HaoBaEvery roof mounted ventilator — especially units equipped with Centrifugal Roof Ventilators — requires regular maintenan...Read More

-

Feb 13, 2026_HaoBaWater leakage through roof ventilation is a concern for many building owners, especially those using a roof mounted vent...Read More

-

Feb 06, 2026_HaoBaA roof mounted ventilator — especially when equipped with Centrifugal Roof Ventilators — is a critical component in indu...Read More

-

Jan 29, 2026_HaoBaIn applications from industrial ventilation to equipment cooling, many users consider an External Rotor Axial Fan when d...Read More

Roof Ventilator Industry Knowledge Extension

Centrifugal Roof Ventilators

In many commercial and industrial buildings, managing internal airflow is not just a matter of comfort—it’s essential to maintain safe and functional environments. Centrifugal roof ventilators are a key component in achieving that goal. Unlike axial fans that move air in a straight line, centrifugal ventilators use a rotating impeller to draw air into the center and then discharge it at a right angle through centrifugal force. This design allows for stronger static pressure and more controlled airflow, which is particularly useful in buildings where long duct runs or resistance is present.

These ventilators are often installed on rooftops to provide continuous extraction of stale air, fumes, or excess heat. Whether used in a kitchen exhaust system, a chemical storage facility, or a multi-story warehouse, centrifugal roof ventilators help maintain cleaner, drier, and more balanced internal environments. Their robust construction typically allows for operation in dusty or humid conditions, while their ability to operate under various pressure conditions makes them a flexible choice for engineers designing HVAC systems.

Proper sizing, placement, and motor selection all contribute to the performance of centrifugal roof ventilators. If installed thoughtfully, they not only improve indoor air quality but can also contribute to energy savings by reducing the need for mechanical cooling in some areas. When paired with speed controllers or automated ventilation systems, their performance can be adjusted based on internal temperature or air quality metrics, further enhancing efficiency and comfort within the building.

Industrial Roof Ventilation Fan

When dealing with large-scale industrial operations such as metalworking, plastic extrusion, food processing, or textile manufacturing, heat and airborne contaminants can accumulate quickly. To address these issues, many facilities rely on an industrial roof ventilation fan to provide consistent airflow and thermal regulation throughout the workspace. These fans are specifically built for durability and high air movement capacity, often featuring weather-resistant housing, heavy-duty motors, and corrosion-resistant materials.

One of the key benefits of an industrial roof ventilation fan is its ability to move large volumes of air with minimal noise, especially when designed with aerodynamic blades and vibration-dampening mounts. In operations where machinery generates heat continuously, these fans can help remove hot air and prevent heat buildup under the roof, which often acts as a trap for rising warm air. This process not only protects equipment from overheating but also contributes to a more tolerable environment for workers, reducing fatigue and increasing productivity.

Industrial fans can be either powered by electricity or integrated into passive systems where wind or thermal uplift supports the exhaust. When used in conjunction with wall louvers or intake vents, they help maintain a crossflow of air, pushing out hot or contaminated air and drawing in fresher outside air. Maintenance is relatively straightforward, involving routine checks on motor function, blade alignment, and any moving parts exposed to wear. With proper care, these fans often deliver years of reliable service even in harsh environments.

Factory Roof Ventilation Fan

Factories present unique challenges in air management due to their enclosed layouts, varied production processes, and large equipment. A factory roof ventilation fan is typically designed to address these conditions by offering consistent removal of warm, stale, or polluted air directly from the top of the building. Positioned to align with rising air currents, these fans take advantage of natural thermal dynamics while supplementing airflow with mechanical support.

The design of a factory roof ventilation fan often includes protective features like bird screens, rainproof cowls, and UV-resistant materials. Some models are constructed for upward air discharge, while others can be customized for horizontal expulsion, depending on the internal layout and external surroundings. This flexibility allows facility managers to configure ventilation systems that address specific needs—whether that’s reducing the concentration of airborne particles, lowering humidity near sensitive production lines, or simply regulating temperature on upper factory floors.

Energy efficiency is a growing consideration for factory operators, and roof ventilation fans can play a role in lowering cooling demands, especially during warmer months. By allowing hot air to exit from the roof level, these fans reduce reliance on air conditioning systems or spot coolers. Some facilities choose to connect their ventilation fans to control systems that monitor indoor climate data, enabling automated fan speed adjustments based on production schedules or occupancy levels.

Additionally, proper ventilation helps maintain compliance with workplace air quality regulations, especially in industries that use solvents, adhesives, or other airborne chemicals. A well-installed factory roof ventilation fan doesn’t just contribute to comfort—it becomes part of a broader safety and compliance strategy.

English

English русский

русский عربى

عربى