Fans For Paint Booths: Safety And Airflow Requirements

2025-07-08

Paint booths play a critical role in providing a controlled environment for applying coatings safely and efficiently. One of the more important aspects of maintaining a paint booth is ensuring proper ventilation and airflow. This is where the choice and performance of fans become essential. Specifically, centrifugal air blowers, air flow ventilators, and axial blowers are commonly used to achieve the necessary air movement and safety standards in paint booths.

A paint booth requires a carefully designed ventilation system to remove hazardous fumes and maintain air quality. The use of centrifugal air blowers is common in such settings because of their ability to generate high pressure and consistent airflow. These blowers push air through filters and exhaust systems, helping to prevent the buildup of volatile organic compounds (VOCs) that are typical in paint spray environments. Centrifugal air blowers are especially effective in overcoming resistance caused by filters or long duct runs, ensuring that contaminated air is reliably expelled.

In addition to centrifugal air blowers, air flow ventilators play a significant role in maintaining the correct airflow patterns inside paint booths. These ventilators are designed to create a steady, controlled air movement, which helps in capturing overspray and directing fumes away from workers. Proper placement and sizing of air flow ventilators ensure that fresh air is continuously supplied while contaminated air is removed efficiently. This not only improves worker safety but also enhances the quality of the paint finish by reducing airborne particles.

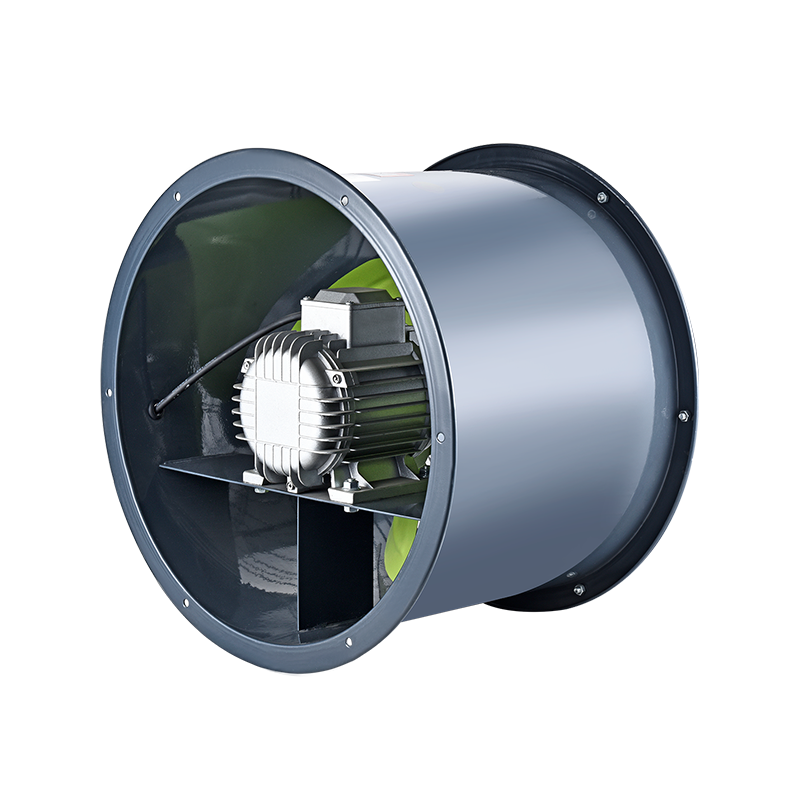

Axial blowers are another common type of fan used in paint booth ventilation systems. Unlike centrifugal air blowers, axial blowers move air in a straight line, which makes them suitable for applications requiring high airflow volumes with relatively low resistance. In paint booths, axial blowers are often used for exhaust or supply air systems where the ductwork is straightforward and pressure loss is small. Their ability to move large volumes of air helps maintain the necessary air exchange rates that keep the environment safe and compliant with regulations.

Safety is a primary concern when designing ventilation for paint booths. The flammable nature of many paint materials means that fans must not only provide sufficient airflow but also operate in a manner that reduces the risk of ignition. Centrifugal air blowers used in paint booths are often constructed with explosion-proof features or materials that less sparks. Similarly, air flow ventilators and axial blowers need to be selected carefully to meet safety certifications relevant to hazardous locations. Ensuring these fans meet specific safety requirements helps protect both personnel and property.

Beyond safety, maintaining the right airflow balance is crucial to prevent cross-contamination and maintain consistent paint quality. Centrifugal air blowers contribute to this balance by delivering stable pressure and airflow even under varying conditions, such as filter loading or changes in environmental factors. Air flow ventilators ensure that air is evenly distributed across the paint booth, preventing areas of stagnant air where fumes or overspray might accumulate. Meanwhile, axial blowers provide the volume of airflow necessary to flush out contaminants rapidly.

In many paint booth setups, a combination of centrifugal air blowers, air flow ventilators, and axial blowers is used to meet the complex demands of the system. Centrifugal air blowers typically handle the higher-pressure sections of the ductwork, pushing or pulling air through restrictive filters or long exhaust pipes. Air flow ventilators manage the directional airflow within the booth, supporting proper circulation patterns. Axial blowers assist in moving large volumes of air quickly when pressure demands are lower. This combined approach allows for a more efficient and reliable ventilation system.

Regular maintenance of these fans is also essential to keep paint booths operating safely and effectively. Centrifugal air blowers require periodic inspection of impellers and bearings to ensure smooth operation. Air flow ventilators must be checked for debris or blockages that could disrupt airflow patterns. Axial blowers should be cleaned regularly to maintain blade efficiency and prevent imbalance. Neglecting maintenance can lead to reduced airflow, higher energy consumption, and increased safety risks.

In conclusion, selecting the right fans for paint booths involves careful consideration of airflow requirements and safety standards. Centrifugal air blowers, air flow ventilators, and axial blowers each play a distinct role in creating a safe, well-ventilated environment. By understanding their specific functions and operating characteristics, paint booth operators can ensure effective removal of hazardous fumes and maintain the quality of their finishing process. Proper design, installation, and maintenance of these fans contribute significantly to both safety and productivity in paint booth applications.

English

English русский

русский عربى

عربى