Noise Reduction Techniques In Ventilation Fan Design

2025-07-08

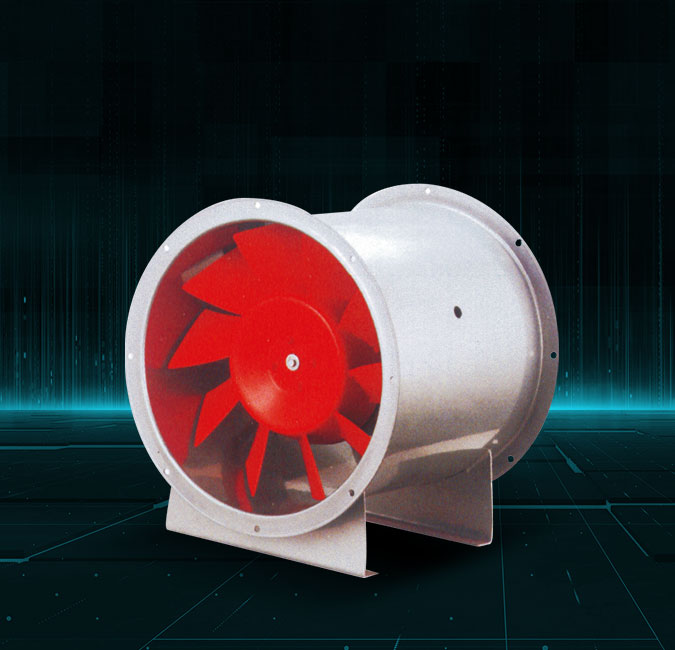

Noise is a common concern when it comes to ventilation fans used in both industrial and commercial environments. Whether it’s a roof blower managing airflow on a factory rooftop or a centrifugal ventilation fan installed in an HVAC system, reducing noise contributes not only to a more comfortable environment but also to better overall system performance. Engineers and designers employ several noise reduction techniques during the development of ventilation fans, including roof blowers and axial centrifugal fans, to address these challenges effectively.

One of the fundamental sources of noise in ventilation fans comes from the airflow itself. When air moves through a centrifugal ventilation fan, it can create turbulence, which generates unwanted sound waves. To reduce this, designers focus on refining the shape of the impeller blades and the housing to ensure smoother airflow. For example, roof blowers often use carefully curved blades and aerodynamic casings to less vortex formation and reduce noise generation. Similarly, axial centrifugal fans are engineered with blade angles optimized to reduce airflow separation and less the sound caused by turbulence.

Another common noise source is mechanical vibration. The rotating components of a centrifugal ventilation fan or an axial centrifugal fan can induce vibrations that transfer noise to the building structure or surrounding equipment. To counter this, vibration isolators and flexible mounts are frequently integrated into roof blower installations and fan assemblies. These mounts absorb vibrations, preventing them from traveling through ducts or mounting surfaces, thereby lowering the perceived noise level. Additionally, maintaining precise balancing of the fan’s rotating parts helps avoid uneven forces that could increase vibration and noise.

Sound insulation is also a key technique used in reducing noise from ventilation fans. Roof blowers are sometimes housed within specially designed enclosures or silenced cabinets that absorb and block sound transmission. These enclosures often include layers of sound-absorbing materials such as foam or mineral wool, which dampen noise while allowing for proper airflow and heat dissipation. For centrifugal ventilation fans installed indoors, acoustic panels or lining within the ductwork can serve a similar function, reducing noise as air passes through the system. Axial centrifugal fans can also benefit from these measures, especially in settings where noise sensitivity is high.

The design of the fan’s motor and drive system can influence noise levels as well. Fans such as roof blowers and centrifugal ventilation fans may employ motors with quieter bearings and optimized rotational speeds to reduce mechanical noise. Variable speed drives allow the fan to operate at lower speeds when full airflow is not necessary, resulting in a reduction in noise output. This is especially useful for axial centrifugal fans in applications where airflow demands fluctuate throughout the day. By matching motor speed to real-time ventilation needs, noise can be kept under control without sacrificing performance.

Finally, careful attention to installation practices plays a significant role in noise reduction. Even the quietest roof blower or centrifugal ventilation fan can generate excessive noise if installed improperly. Ensuring secure and vibration-isolated mounting, avoiding rigid connections that transmit sound, and positioning the fan away from noise-sensitive areas can help reduce sound impact. Moreover, regular maintenance such as cleaning blades and checking for wear can prevent issues that might cause increased noise, such as imbalance or mechanical wear in axial centrifugal fans.

In conclusion, reducing noise in ventilation fan design is a multifaceted challenge that involves aerodynamic improvements, vibration control, sound insulation, motor optimization, and proper installation. Roof blowers, centrifugal ventilation fans, and axial centrifugal fans each present unique opportunities for noise reduction, and applying these techniques can improve user comfort and system efficiency. By addressing both airflow-related and mechanical noise sources, manufacturers and engineers continue to develop quieter ventilation solutions suitable for a wide range of industrial and commercial applications.

English

English русский

русский عربى

عربى