Using Industrial Blowers In Dust Collection Systems

2025-07-08

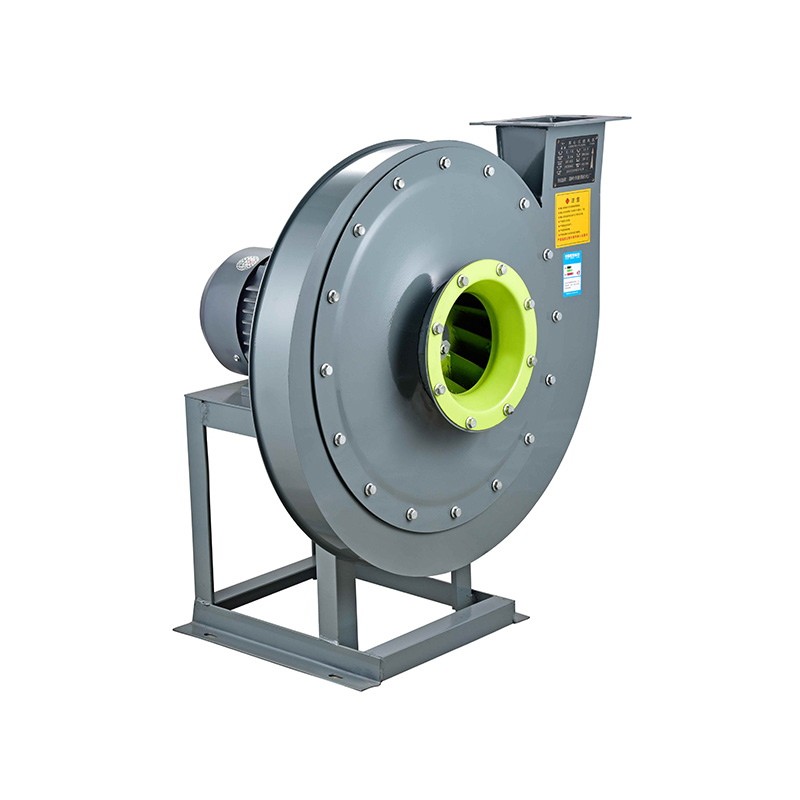

Dust collection systems play a critical role in maintaining air quality and safety across various industrial environments. One of the key components in these systems is the industrial blower, which helps to efficiently move air and capture dust particles. Among the different types of industrial blowers, cabinet type centrifugal fans, domestic centrifugal fans, and roof centrifugal fans are commonly used to meet specific operational needs. Understanding how these blower types function within dust collection systems can help ensure effective dust control and long-lasting equipment performance.

Cabinet type centrifugal fans are widely utilized in dust collection setups due to their enclosed design, which helps protect internal components from dust accumulation and damage. The cabinet housing offers an additional layer of protection, making these fans suitable for heavy-duty applications where dust and particulate matter can be highly abrasive. In many dust collection systems, cabinet type centrifugal fans provide consistent airflow and pressure, which is essential to maintain the efficiency of dust capture devices such as baghouses or cartridge filters. Their robust construction also allows them to handle varying air volumes without significant drops in performance.

In smaller-scale or localized dust extraction systems, domestic centrifugal fans often come into play. While these fans are generally designed for less demanding environments, their compact size and quieter operation make them practical for workshops, laboratories, or light industrial areas. Domestic centrifugal fans are typically easier to install and maintain, which helps reduce downtime and operating costs in facilities that do not require large-capacity ventilation. Despite their smaller size, these fans can still provide reliable airflow to maintain clean working conditions and protect workers from dust exposure.

Roof centrifugal fans serve a different but equally important role in dust collection systems. Mounted on rooftops, these fans are designed to exhaust contaminated air outside the building efficiently. The positioning of roof centrifugal fans allows for better dispersal of dust-laden air, with less chance of re-entrainment inside the facility. Additionally, their installation on rooftops reduces noise transmission within the building, contributing to a more comfortable working environment. Roof centrifugal fans are engineered to withstand outdoor conditions, including exposure to weather elements, which makes them a durable choice for long-term dust extraction operations.

One of the advantages of integrating cabinet type centrifugal fans in dust collection systems is the ease with which they can be incorporated into modular setups. Their enclosure design helps simplify duct connections and facilitates easier access for inspections and repairs. This feature is particularly important in systems where continuous operation is critical and maintenance windows are limited. By using cabinet type centrifugal fans, facility managers can ensure that airflow remains steady, which directly impacts the effectiveness of dust capture.

Domestic centrifugal fans, although less industrial in scale, can be customized with various impeller designs to optimize airflow for specific dust collection needs. This adaptability allows these fans to be used in a range of industries, from woodworking to electronics manufacturing, where dust particle sizes and types vary. Their quieter operation is also a consideration for facilities aiming to reduce noise pollution while maintaining clean air. Regular maintenance of domestic centrifugal fans helps prolong their service life and keeps dust collection systems functioning smoothly.

Roof centrifugal fans complement these systems by handling the final stage of dust exhaust. Their high-velocity discharge capability ensures that dust particles are effectively carried away from the building envelope. Proper installation and selection of roof centrifugal fans can reduce the risk of recirculation of contaminated air, which is vital for maintaining indoor air quality standards. Moreover, these fans often come with weather-resistant features that protect motors and other components, reducing the frequency of repairs or replacements.

Together, cabinet type centrifugal fans, domestic centrifugal fans, and roof centrifugal fans form an integrated network that supports effective dust collection across various industrial scenarios. Each fan type addresses unique challenges — cabinet type centrifugal fans focus on robust protection and steady airflow, domestic centrifugal fans offer compact and quieter solutions, and roof centrifugal fans ensure proper exhaust and environmental protection.

In summary, choosing the appropriate type of industrial blower is essential for the design and operation of dust collection systems. Whether it is the protective enclosure of cabinet type centrifugal fans, the versatility of domestic centrifugal fans, or the outdoor resilience of roof centrifugal fans, each contributes to maintaining a cleaner and safer workplace. By understanding the functions and advantages of these fans, industries can implement dust control measures that comply with safety regulations and promote healthier working conditions.

English

English русский

русский عربى

عربى