Product

Multi-Blade Fan Wholesaler

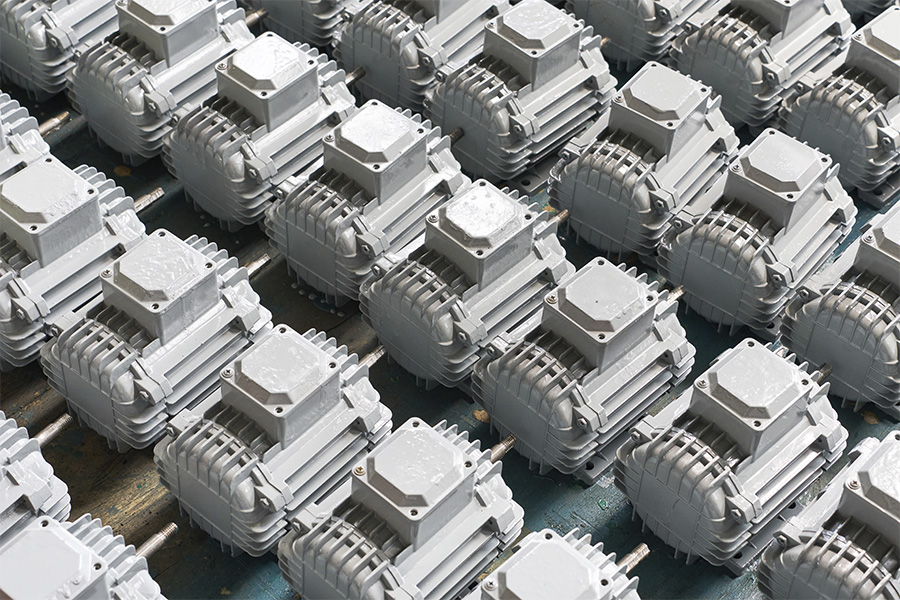

Multi-wing fans are an important category in the HAOBA fan product line, designed for industrial environments that require high wind pressure and stable airflow. Its notable feature is that it is equipped with multiple wide blades, which are precisely designed to effectively increase the static pressure and air volume of the fan, ensuring more uniform and efficient air delivery. The impeller structure of the multi-wing fan is sturdy and durable, runs smoothly, has low vibration and noise, and is suitable for long-term continuous work.

From the manufacturer's point of view, HAOBA multi-wing fans have the advantages of high efficiency, energy saving, environmental protection, and strong adaptability. They can maintain outstanding air volume and pressure output in complex pipelines and systems with high resistance, while being simple to maintain and having a long service life. Multi-wing fans are widely used in air purification, HVAC systems, industrial dust removal equipment, mechanical cooling, and heat dissipation of electronic equipment.

With precise design and strict manufacturing processes, HAOBA multi-wing fans play a key role in ensuring equipment performance and improving system operating efficiency, and have become a trusted choice for many industry customers.

-

Feb 20, 2026_HaoBaEvery roof mounted ventilator — especially units equipped with Centrifugal Roof Ventilators — requires regular maintenan...Read More

-

Feb 13, 2026_HaoBaWater leakage through roof ventilation is a concern for many building owners, especially those using a roof mounted vent...Read More

-

Feb 06, 2026_HaoBaA roof mounted ventilator — especially when equipped with Centrifugal Roof Ventilators — is a critical component in indu...Read More

-

Jan 29, 2026_HaoBaIn applications from industrial ventilation to equipment cooling, many users consider an External Rotor Axial Fan when d...Read More

Multi-Wing Fan Industry Knowledge Extension

Multi Wing Fan Factory: The Foundation of Quality Production

A Multi Wing Fan Factory serves as the backbone of the air movement equipment industry. These manufacturing facilities are responsible for designing and producing fans used across ventilation, air-conditioning, refrigeration, and industrial systems. The strength of a factory lies in its ability to consistently meet performance standards, maintain quality control, and adapt to diverse technical specifications.

In such factories, precision tools and automated processes are commonly used to mold, balance, and assemble multi-wing impellers. Materials such as aluminum, plastic, and galvanized steel are selected based on their durability, weight, and resistance to corrosion. Manufacturing also involves rigorous balancing procedures to reduce vibration and noise during operation. Furthermore, a well-equipped multi wing fan factory has the flexibility to produce fans in different blade counts, angles, and diameters, allowing for customization to meet specific airflow and pressure requirements.

Customer needs often vary based on installation environment—such as HVAC systems, electronic cabinet cooling, or greenhouse ventilation—and factories must be equipped to handle both batch production and unique design requests. A factory that integrates both engineering knowledge and adaptable machinery plays a key role in keeping up with industry demands.

Multi Wing Fan: Versatility in Airflow Control

The Multi Wing Fan is designed for versatility, capable of handling a wide range of airflow and static pressure conditions. It typically consists of several narrow blades mounted at specific angles on a central hub. These blades are evenly spaced and carefully balanced, which helps ensure uniform airflow and lower noise during operation.

Multi wing fans are commonly used in applications requiring compact, efficient air movement. From duct ventilation to air handling units, they offer flexibility in performance without occupying large amounts of space. The multiple blade configuration allows the fan to move air efficiently in confined environments, where large axial or centrifugal fans may not be suitable.

They can be mounted directly to motors or integrated into blower assemblies, and their modular design makes maintenance or replacement relatively simple. Multi wing fans are also frequently used in appliances and equipment where consistent, stable airflow is required. Because of their balance between performance and size, they serve as a practical solution in various air system designs.

Multi-Blade Fan: Enhanced Stability and Pressure Handling

A Multi-Blade Fan refers to a fan equipped with a high number of blades, typically more than traditional axial fans. The increased number of blades improves pressure build-up and enhances stability during operation, especially in systems where air needs to be pushed through filters or ductwork.

These fans are particularly useful in situations where quiet performance is required alongside strong air delivery. More blades mean each individual blade does less work per revolution, resulting in lower turbulence and smoother flow. This design can reduce vibration, especially when the fan is used in sound-sensitive environments such as office buildings, hospitals, or laboratories.

Multi-blade fans are often found in air conditioning condensers, cleanroom ventilation, and high-performance cooling systems. Because they offer a good balance between air volume and pressure capacity, they are suitable for medium-duty to heavy-duty airflow applications. Their design also makes them less sensitive to small changes in static pressure, which contributes to more stable system operation over time.

Multi-Vane Fan: Targeted Efficiency in Compact Spaces

The Multi-Vane Fan is a type of fan that uses short, closely spaced vanes to generate directional airflow. These vanes are often curved or angled to allow for specific airflow characteristics, particularly when space is limited or when directional control is essential.

Multi-vane fans are commonly found in air handling systems where targeted airflow is necessary. Their design is especially useful in environments that require directional exhaust or intake, such as in switchgear rooms, electrical cabinets, or small ventilation ducts. The compact nature of the vane arrangement allows the fan to generate focused airflow with relatively low energy input.

One of the strengths of the multi-vane configuration is its ability to produce consistent flow at lower speeds, which can help reduce wear and energy consumption. Additionally, these fans are often chosen for installations where airflow needs to be directed through baffles or tight spaces without losing efficiency. Because of their design, they can be easily integrated into modular HVAC systems and localized cooling units.

English

English русский

русский عربى

عربى