Noise and Vibration Issues in Axial Flow Fan Operation

2026-01-09

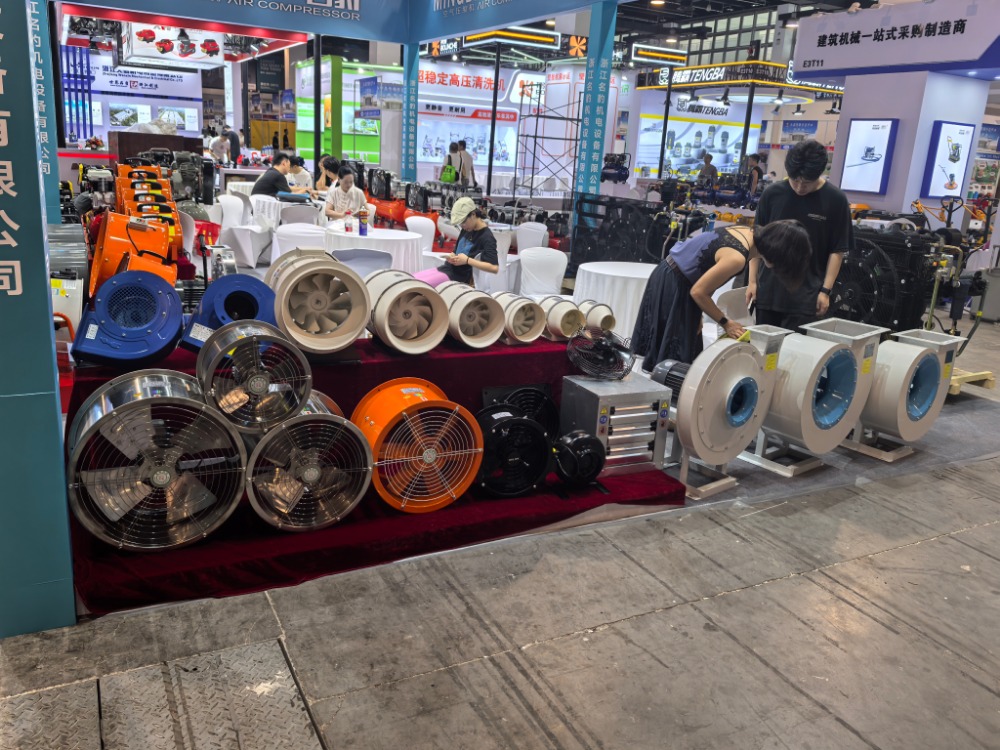

In industrial ventilation systems and cooling applications, choosing the right Axial Flow Fan Manufacturer is just the beginning. Many users also encounter performance concerns such as unwanted noise and vibration during long‑term operation, whether the application involves a duct‑mounted blower or an External Rotor Axial Fan integrated into machinery. Understanding the root causes of these issues and how to address them improves equipment reliability and user satisfaction.

Why Noise Happens in Axial Flow Fans

Noise generation in axial fans can stem from several mechanical and aerodynamic sources:

Aerodynamic turbulence around blades: Uneven airflow over the fan blades can create unwanted noise. As air passes over the blade surface, pressure fluctuations and turbulence produce audible sound waves. Blade design, RPM, and airflow conditions all influence this effect.

Mechanical vibration transmission: Vibration from the motor, bearings, or fan housing often travels through mounting structures, amplifying sound. In some installations with less rigid supports, this phenomenon is more pronounced.

Debris and obstruction: Dust, foreign objects, or debris in the airflow path can disturb the flow and trigger noise. These disturbances not only reduce fan efficiency but also make fans louder over time.

Noise is not just an annoyance — in environments like offices, hospitals, or manufacturing floors, excessive sound levels can violate comfort or compliance standards. Identifying the source quickly helps optimize performance and reduce unnecessary downtime.

Common Vibration Challenges

Vibration in axial fans normally relates to balance, alignment, or structural stiffness issues. Some frequent contributors include:

Imbalanced fan blades: If blades accumulate dust more on one side than the other, or if blades have slight shape variations, the rotor can spin unevenly. This imbalance results in vibration that may stress bearings and mounts.

Misalignment between motor and shaft: Proper alignment ensures smooth rotation and stable operation. When parts are misaligned, even slightly, vibration increases and can accelerate wear.

Weak mounting or support: Especially for larger axial units, insufficient structural stiffness allows the entire assembly to resonate under load, increasing vibration amplitudes.

Vibration can significantly shorten the lifespan of key components — including blades, bearings, and the motor itself — if left unchecked.

Inspection and Troubleshooting Checklist

Below is a practical sequence for diagnosing noise and vibration issues in an axial fan or an external rotor unit:

Visual Inspection:

Start by checking for obvious obstructions, bent blades, or debris lodged in the fan housing.

Clean and Balance:

Clean the blades and use dynamic balancing if vibration persists, ensuring the rotor spins evenly at operating speed.

Check Bearings and Lubrication:

Worn bearings cause noise and vibration. Replace worn bearings and ensure proper lubrication is in place.

Examine Mounts and Foundation:

Tighten loose bolts, reinforce mounting brackets, and improve the structural stiffness where feasible.

Maintenance Recommendations

To keep your axial flow fans operating quietly and smoothly over time, implement a scheduled maintenance program:

Routine Cleaning: Regularly remove dust and debris, especially in dusty environments.

Periodic Vibration Analysis: Using vibration sensors or periodic checks can catch issues before they become serious.

Record Operating Conditions: Tracking noise levels and vibration trends over time helps forecast part wear and plan replacements.

Consistent maintenance not only improves user experience but also safeguards energy efficiency and system uptime.

Enhancing Fan Performance

Issues like noise and vibration won’t always be avoided, but they can be managed effectively. Whether you’re using an External Rotor Axial Fan for equipment cooling or industrial airflow, understanding the mechanical and aerodynamic sources of unwanted sound and movement helps in selecting the right Axial Flow Fan Manufacturer and optimizing your setup.

At Taizhou Haoba Electromechanical Co., Ltd., we emphasize delivering reliable axial fan solutions designed with performance and durability in mind. With proper installation and upkeep, axial fans can operate quietly and efficiently for years.

English

English русский

русский عربى

عربى