Product

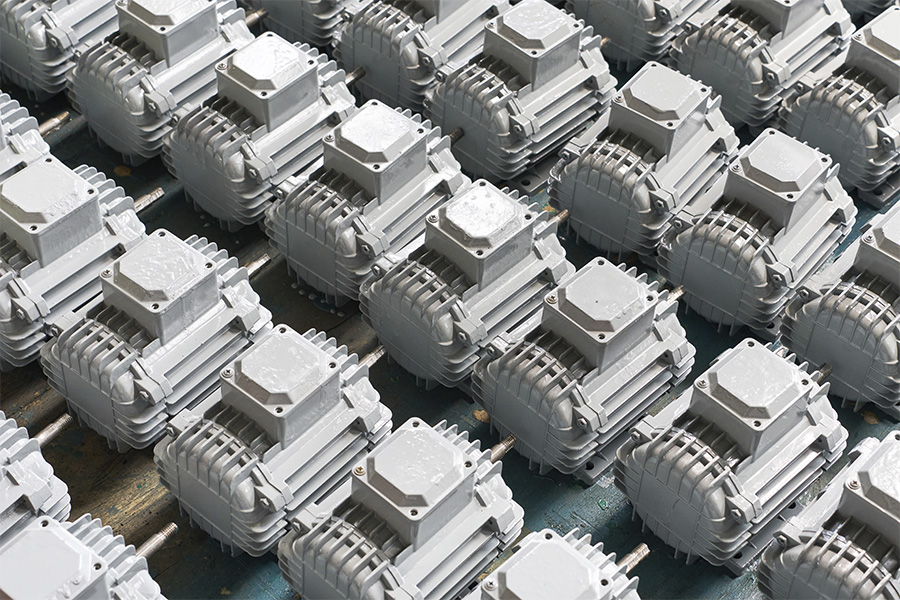

Wholesale Industrial Axial Flow Fan

As a professional fan equipment manufacturer, HAOBA has rich design and production experience in the field of axial flow fans. Axial flow fans are one of the core categories in our ventilation product system. Their main features are that the airflow flows along the axis of the fan, with a simple structure, large air volume, and flexible installation. They are widely used in industrial and civil fields.

The axial flow fans produced by HAOBA generally use high-quality metal materials, optimized blade design, and high-efficiency outer rotor motors to ensure that the products have the advantages of low noise, low vibration, high efficiency and strong reliability during operation. Its common characteristics also include strong energy saving, easy maintenance, wide adaptability, and suitable for a variety of complex environments.

This type of fan is widely used in factory workshops, warehouses, grain depots, tunnels, farms, machine rooms, kilns, and electronic equipment for ventilation, heat dissipation, or enhanced air circulation. HAOBA is committed to providing customers with axial flow ventilation solutions with outstanding performance and convenient use.

-

Feb 20, 2026_HaoBaEvery roof mounted ventilator — especially units equipped with Centrifugal Roof Ventilators — requires regular maintenan...Read More

-

Feb 13, 2026_HaoBaWater leakage through roof ventilation is a concern for many building owners, especially those using a roof mounted vent...Read More

-

Feb 06, 2026_HaoBaA roof mounted ventilator — especially when equipped with Centrifugal Roof Ventilators — is a critical component in indu...Read More

-

Jan 29, 2026_HaoBaIn applications from industrial ventilation to equipment cooling, many users consider an External Rotor Axial Fan when d...Read More

Axial Flow Exhaust Fan Industry Knowledge Extension

Axial Flow Fan Manufacturer

An axial flow fan manufacturer plays a key role in delivering customized ventilation solutions across a wide range of industries. Axial fans, which move air in a straight line parallel to the fan shaft, are essential for applications requiring high airflow rates and low to medium pressure. As a dedicated manufacturer, we combine technical expertise with in-house production capabilities to offer high-performance axial flow fans tailored to customer requirements.

From design to final assembly, every stage of production is strictly controlled. Engineers focus on aerodynamic blade design, durable materials, and motor compatibility to ensure reliable and energy-efficient performance. Whether the application is for industrial cooling, air exchange in commercial spaces, or process ventilation in factories, our manufacturing facility is equipped to produce fans that match precise specifications. We also support customization in terms of blade materials, motor configurations, coatings for corrosive environments, and size variations. Our goal as a professional axial flow fan manufacturer is not just to produce fans, but to provide integrated air movement solutions that improve efficiency and reliability in real-world operations.

Axial Flow Exhaust Fan

Axial flow exhaust fans are commonly used in ventilation systems where stale, heated, or contaminated air must be removed quickly and efficiently. Their design allows air to flow along the axis of the fan, making them ideal for applications that require direct and unobstructed air movement. These fans are typically mounted on walls, ceilings, or ducts, depending on the installation environment.

In commercial kitchens, warehouses, parking garages, and workshops, axial flow exhaust fans help control temperature, remove fumes, and maintain acceptable air quality standards. Their high airflow capacity and low power consumption make them a preferred choice in both temporary and permanent ventilation setups. In addition, axial flow exhaust fans are relatively easy to maintain and install, with lightweight structures and straightforward mounting systems.

Fan blade materials can vary depending on the operational environment—from aluminum and plastic for general use to stainless steel for corrosive or high-temperature areas. For increased durability, weather-resistant coatings and sealed motors can also be integrated. Noise levels are another important factor, especially in offices or public areas, and axial flow exhaust fans are often engineered to operate with minimal vibration and low acoustic output. When used properly, these fans contribute significantly to better indoor air quality and overall workplace comfort.

Industrial Axial Flow Fan

An industrial axial flow fan is designed for heavy-duty applications in large-scale production facilities, such as steel mills, chemical plants, power generation stations, and textile manufacturing. These fans are built with robust materials and are designed to handle large volumes of air under challenging conditions.

What distinguishes an industrial axial flow fan from other fan types is its capacity to work continuously in demanding environments while maintaining stable airflow and system efficiency. The fan blades are typically made from reinforced metals or composite materials and are carefully balanced to reduce wear and vibration during high-speed operation. Motor choices include both single-phase and three-phase configurations, often with IP-rated enclosures to protect against dust and moisture ingress.

Industrial axial flow fans are also customizable to meet different airflow requirements. Blade pitch angles can be fixed or adjustable, allowing the fan to be fine-tuned for different pressure and flow scenarios. Some models are belt-driven for speed control flexibility, while others are direct-driven for compact, low-maintenance installations. These fans are essential for cooling machinery, exhausting high-temperature air, and distributing fresh air in enclosed industrial spaces. For businesses looking to maintain smooth production and reduce equipment overheating, investing in high-quality industrial axial flow fans is an effective strategy.

High Pressure Axial Fan

High pressure axial fans are specially engineered for situations where air needs to be forced through long duct systems or where static pressure resistance is high. These fans are often used in applications like tunnel ventilation, underground mining, high-rise buildings, and other confined spaces where conventional fans may not provide sufficient force.

Unlike standard axial fans, high pressure axial fans are designed with advanced blade geometry and reinforced construction to increase airflow velocity and pressure. The blade profile is optimized to handle resistance while minimizing energy loss, and many designs feature adjustable blades to accommodate different system loads. These fans may also incorporate sound-dampening features, thermal protection, and vibration isolation systems to ensure reliable operation in extreme conditions.

Their motors are typically high-power and built for continuous use, with cooling systems to prevent overheating. In addition, the fan housing is usually fabricated from heavy-gauge steel or corrosion-resistant alloys to endure harsh environments. For HVAC engineers and plant designers, high pressure axial fans provide a critical solution for forced ventilation, ensuring adequate airflow in spaces where airflow resistance is too strong for ordinary fans.

Moreover, these fans are also used in cleanroom applications and industrial drying processes, where consistent, high-pressure airflow is required to maintain environmental control and product quality. Their combination of pressure capability, robust design, and performance reliability makes them an important component in complex ventilation systems.

English

English русский

русский عربى

عربى