Product

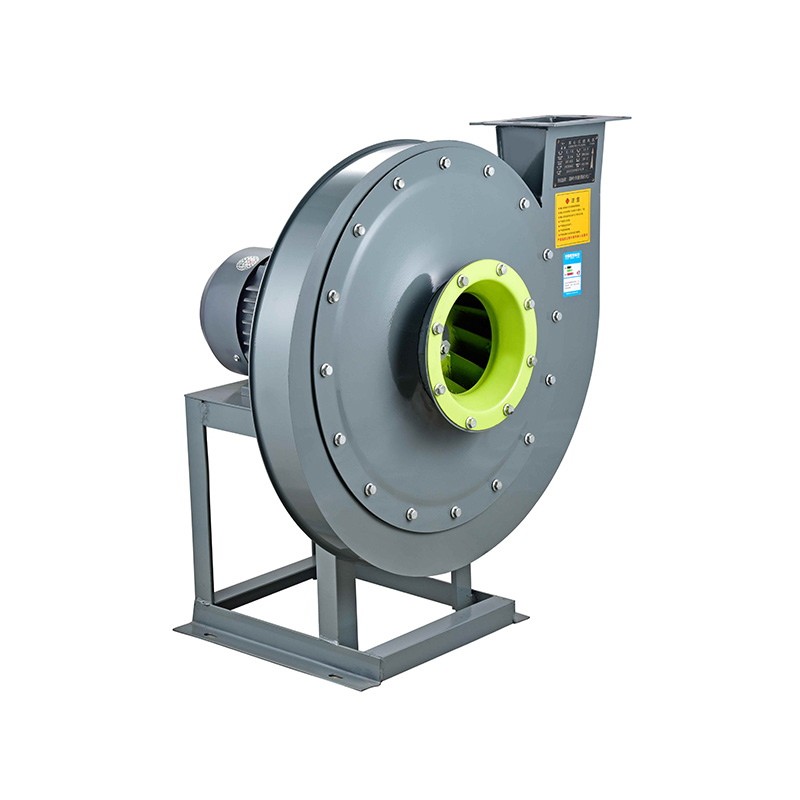

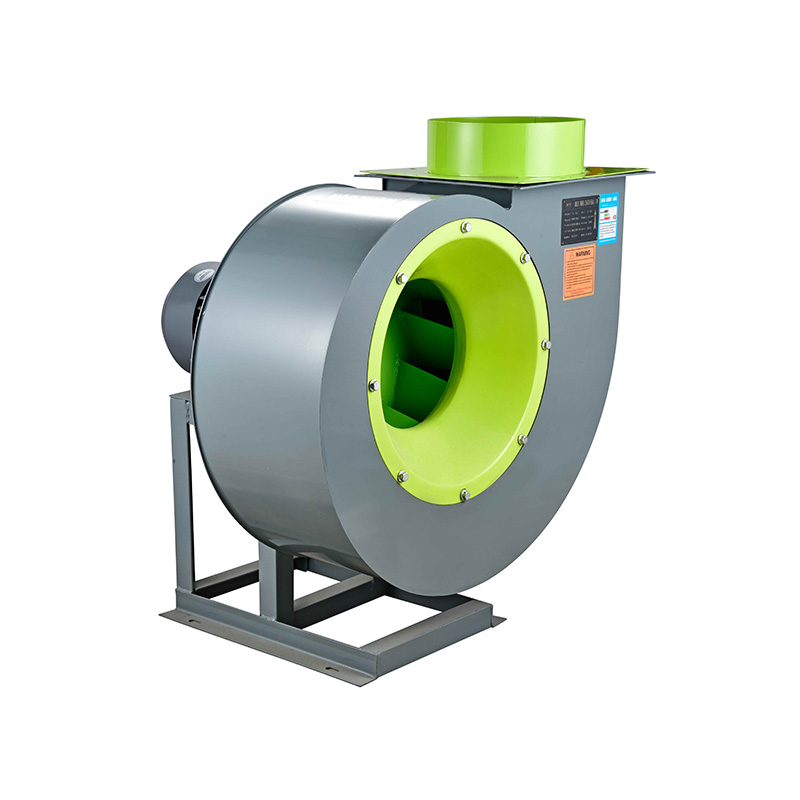

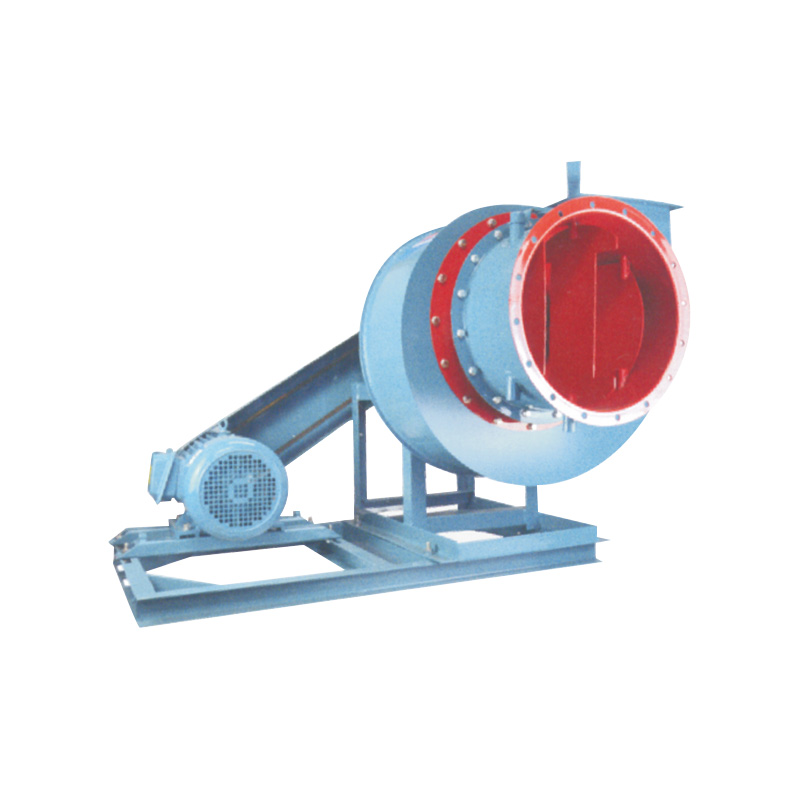

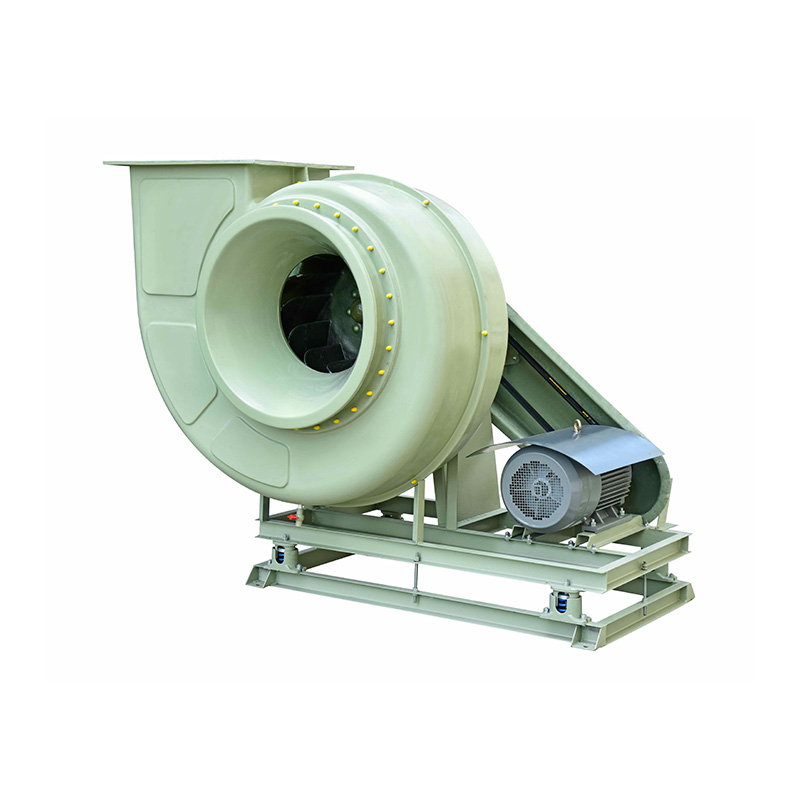

Wholesale Centrifugal Flow Fan Maker

Centrifugal fans are a type of fan widely used in industrial ventilation systems. They have the remarkable characteristics of compact structure, stable performance and strong adaptability. Its working principle is to inhale air from the center of the fan through the high-speed rotation of the fan impeller, and then throw the air to the periphery through the centrifugal force of the impeller, thereby generating a higher wind pressure.

Compared with axial flow fans, centrifugal fans can provide greater pressure and stronger air flow delivery capacity, and are particularly suitable for occasions that need to overcome large pipeline resistance and system pressure.

Centrifugal fans have various impeller designs, including forward-inclined impellers, backward-inclined impellers and radial impellers, which can meet the air volume and air pressure requirements under different working conditions. Its advantages are not only reflected in efficient wind pressure output, but also in smooth operation, low noise and convenient maintenance. Centrifugal fans are suitable for a variety of industries and environments, such as industrial exhaust, air conditioning systems, dust removal equipment, boiler air supply and ventilation and cooling.

As a professional fan manufacturer, HAOBA focuses on the research and development and production of centrifugal fans, and continuously improves product performance and energy efficiency. Through advanced technology and strict quality control, HAOBA centrifugal fans achieve energy conservation and emission reduction while ensuring high air pressure and air volume, helping customers optimize the operating efficiency of ventilation systems.

-

Feb 20, 2026_HaoBaEvery roof mounted ventilator — especially units equipped with Centrifugal Roof Ventilators — requires regular maintenan...Read More

-

Feb 13, 2026_HaoBaWater leakage through roof ventilation is a concern for many building owners, especially those using a roof mounted vent...Read More

-

Feb 06, 2026_HaoBaA roof mounted ventilator — especially when equipped with Centrifugal Roof Ventilators — is a critical component in indu...Read More

-

Jan 29, 2026_HaoBaIn applications from industrial ventilation to equipment cooling, many users consider an External Rotor Axial Fan when d...Read More

Centrifugal Fan Industry Knowledge Extension

Centrifugal Fan Factory: Behind the Manufacturing Process

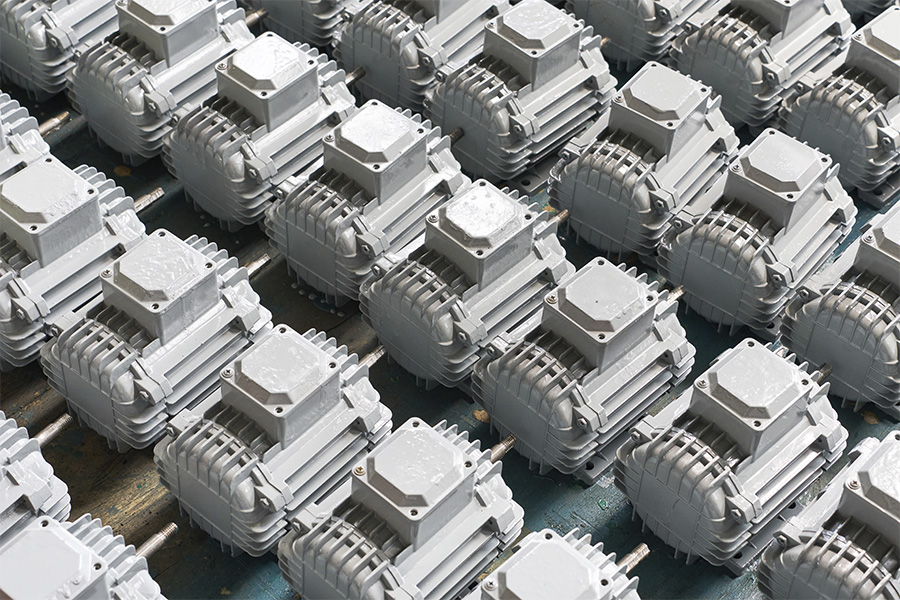

A centrifugal fan factory plays a central role in the supply of industrial ventilation equipment. The production process begins with the careful selection of raw materials, typically sheet metal for the housing and impellers, which are then formed and welded using precision machinery. Skilled technicians work closely with automated systems to ensure consistent quality during fabrication, assembly, and balancing. Each centrifugal fan undergoes multiple inspections, including performance testing, noise level analysis, and durability checks. The focus is not only on output volume but also on long-term reliability and compatibility with different installation environments. These factories often support customization requests, offering a range of sizes, motor options, and configurations to meet specific airflow and pressure requirements. As demand grows across industries such as HVAC, dust collection, and chemical processing, the role of a centrifugal fan factory continues to evolve, incorporating more advanced automation and energy-efficient designs.

Wholesale Centrifugal Fan: Meeting Market Demands Efficiently

The wholesale centrifugal fan market serves a diverse range of clients, from distributors and project contractors to OEM partners and commercial installers. Buying centrifugal fans in bulk can offer cost advantages while also ensuring availability for larger-scale applications. Wholesale orders typically involve a selection of standard models, but some buyers also request modified units to suit their ventilation system layouts. In wholesale transactions, attention is given to packaging, logistics, and after-sales support to ensure smooth integration at the client’s end. The fans supplied in bulk often feature standardized mounting dimensions, voltage ratings, and airflow ranges, making them easy to incorporate into ventilation ducts, production lines, or equipment housings. Wholesale suppliers may stock both forward-curved and backward-curved designs, allowing customers to choose based on airflow characteristics, pressure requirements, and installation space. In many cases, businesses prefer working with wholesalers who can offer consistent quality and reliable timelines without the need for intermediary channels.

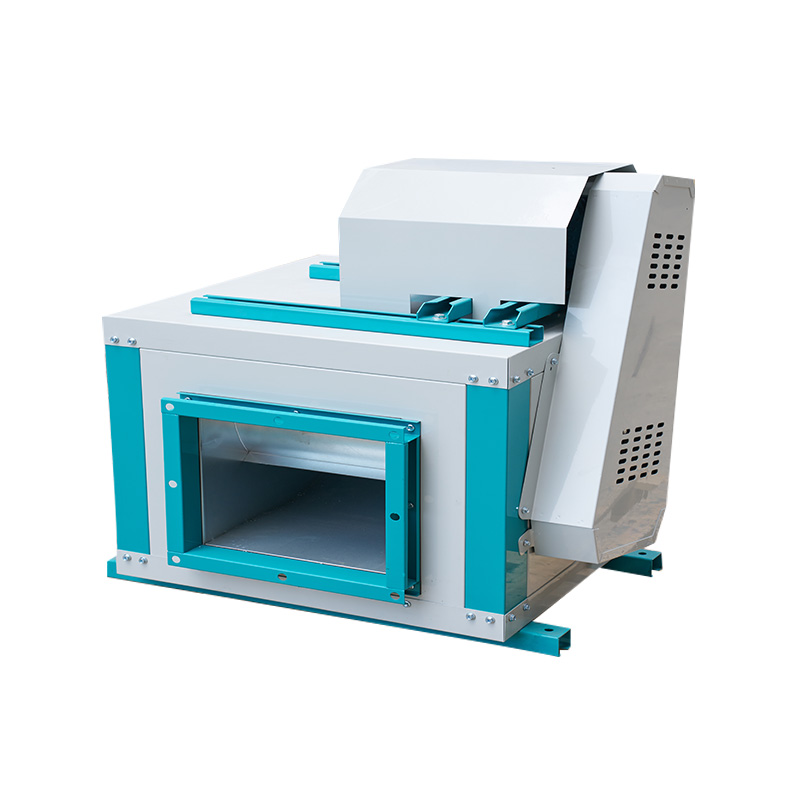

Centrifugal Flow Fan: Design and Performance Characteristics

A centrifugal flow fan works by pulling air into the center of a rotating impeller and pushing it outward at a 90-degree angle. This airflow direction creates higher pressure than axial fans, making centrifugal models more suitable for ducted systems and environments with resistance to airflow. One of the key advantages of the centrifugal flow fan is its ability to operate under varying pressure conditions without significant performance loss. These fans are widely used in air handling units, furnace ventilation, drying systems, and even fume extraction setups. Depending on the specific application, they may come with single or double inlets, scroll housings, and variable blade designs. Sound levels and vibration are also carefully managed through the use of dynamically balanced impellers and vibration-isolated mounting systems. Maintenance access is typically built into the housing design, allowing for regular cleaning and inspection without removing the entire unit. With proper installation and upkeep, a centrifugal flow fan offers consistent airflow in demanding environments.

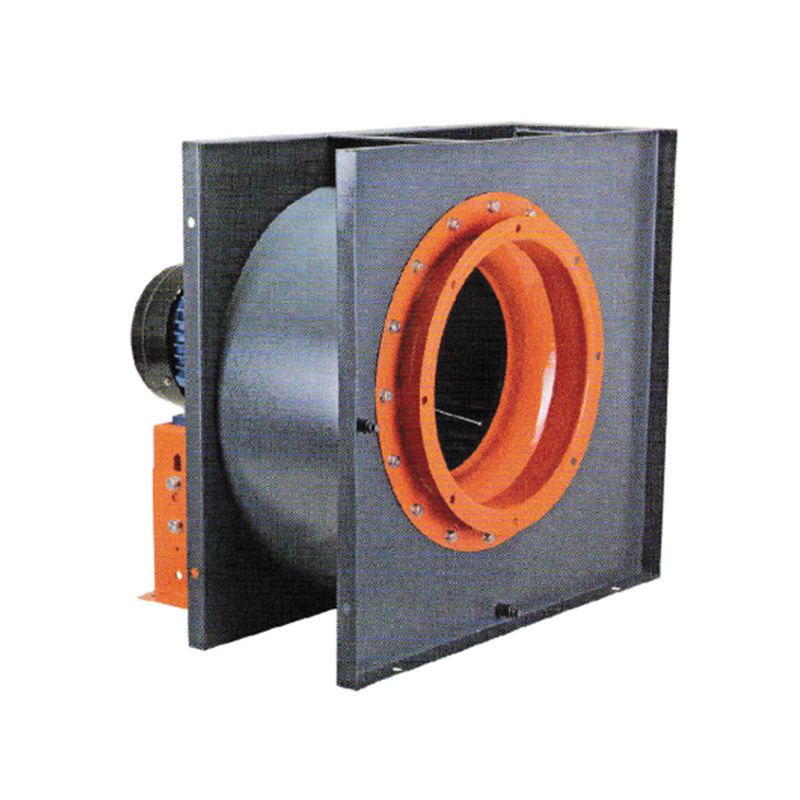

High Pressure Centrifugal Fan Blower: Applications That Require Forceful Air Movement

The high pressure centrifugal fan blower is designed for situations where significant resistance exists in the airflow path. Unlike general-purpose fans, these units are built to move air against high static pressure, which may be caused by long duct runs, filters, heat exchangers, or other components. These blowers often feature smaller impeller diameters with tightly curved blades and operate at higher rotational speeds. The result is a strong, directed stream of air suitable for combustion systems, pneumatic conveying, and industrial drying. Construction materials may include stainless steel, aluminum, or coated carbon steel to withstand corrosive or high-temperature environments. Motor selection is another critical aspect of high pressure centrifugal fan blowers, with many units designed to pair with variable frequency drives for better control over speed and energy consumption. Proper sealing of the casing, precision in impeller construction, and reinforced bearings all contribute to the blower’s ability to maintain pressure output over extended operating hours. When airflow needs to be concentrated and forceful, this type of fan delivers targeted performance.

English

English русский

русский عربى

عربى